High strength nuts are high-strength bolts and are a type of standard component. In general, high-strength bolts can withstand larger loads than ordinary bolts of the same specification.

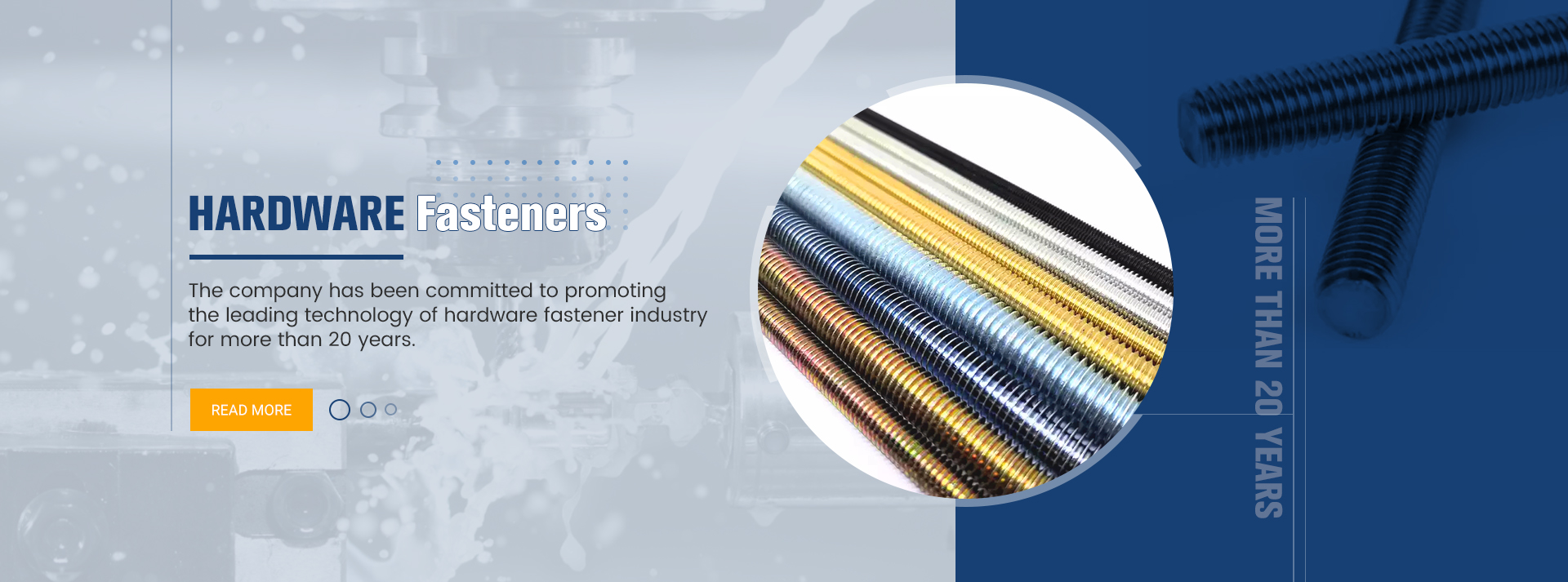

Overview of high-strength nuts

The shape and connection structure of high-strength nuts are basically the same as those of ordinary bolts. The main difference between the two is that ordinary bolt connections rely on the rod body to bear pressure and resist shear to transmit shear force. When tightening the nut, the pre tension force generated by the bolt is very small, and its impact is not considered; The working principle of high-strength nut connection is to intentionally apply a large pre tension force to the bolt, causing a squeezing force between the contact surfaces of the connected parts. Therefore, there is a large frictional force perpendicular to the screw direction, which is used to transmit the connection shear force. The pre tension of high-strength nuts is achieved by tightening the nuts, while ordinary high-strength nuts generally use torque and angle methods. Twisted shear type high-strength nuts use the tail of the bolt to be twisted to control the pre tension.

The bolts for high-strength nut connections are made of high-quality alloy structural steel of 10.9s or 8.8s grade and heat-treated. The high-strength bolt holes should be drilled. The aperture of high-strength bolts for friction type connections is 1.5~2.0mm larger than the nominal diameter d of the bolt; The aperture of high-strength bolts for pressure bearing connections is 1.0-1.5mm larger than the nominal diameter d of the bolt.

Difference between high-strength nuts:

In general, high-strength bolts can withstand larger loads than ordinary bolts of the same specification.

The material of ordinary bolts is q235 (i.e. a3) manufactured.

The material of high-strength bolts is 45 # steel, alloy steel (such as 20mntib, 35VB) or other high-quality materials, which undergo heat treatment after production to improve their strength.

Post time: Sep-03-2024